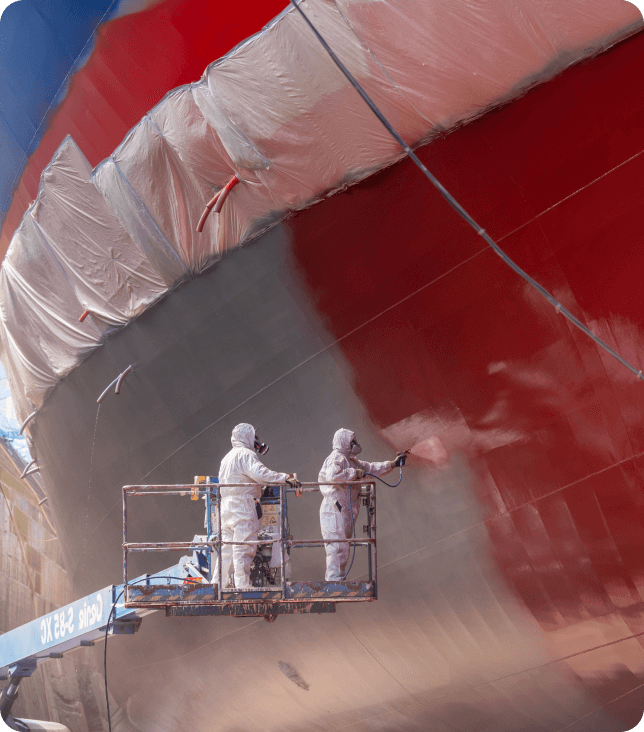

Enhance vessel performance with sustainable graphene-based marine coatings

Reduce fuel consumption and protect the environment with GIT’s biocide-free hard foul release hull and propeller coatings while decarbonizing your fleet.

Reduce fuel consumption and protect the environment with GIT’s biocide-free hard foul release hull and propeller coatings while decarbonizing your fleet.

Sustainable hard foul release coatings that help ship owners and operators improve vessel performance while reducing emissions to air and water.

XGIT-FUEL is a graphene-based hard foul release hull coating that creates an ultra-low friction surface to increase vessel efficiency, and its patented XGIT® technology secures a hydrated layer that deters the settlement and attachment of biofouling.

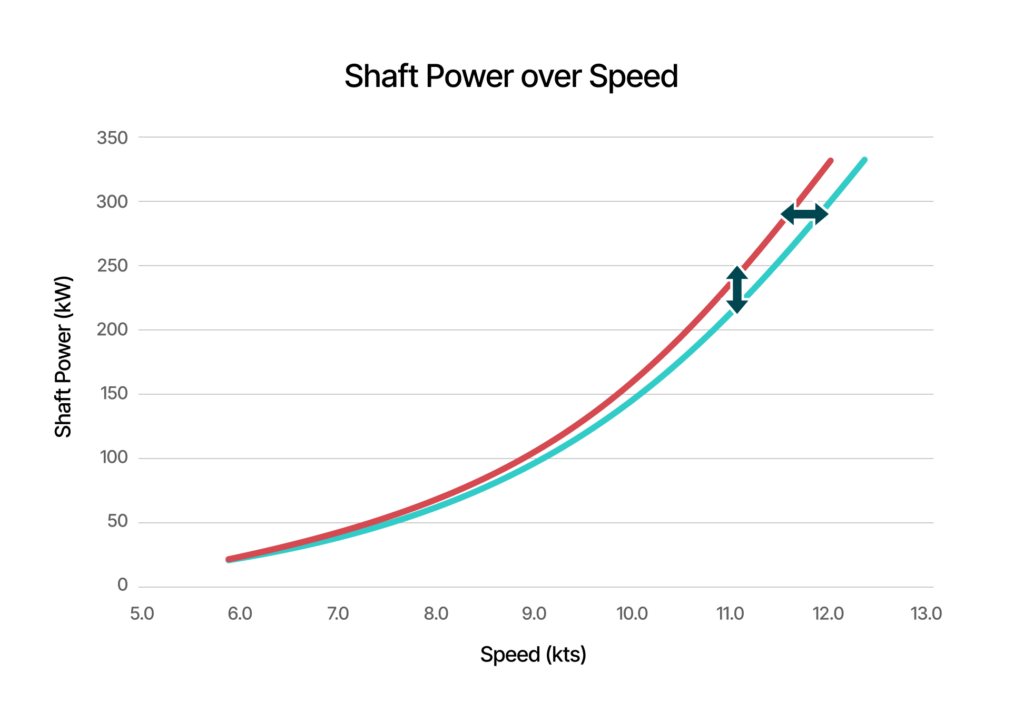

A study conducted by Lloyds Register proved XGIT-FUEL provided an average of 10.43% shaft power reduction at different speeds. Sea trials and data collection was done according to ISO 15016:2015.

XGIT-PROP is a highly durable graphene-based hard foul release propeller coating that helps to improve vessel performance by keeping the propeller smooth over time. It is the most efficient and simplest way to improve and maintain CII rating.

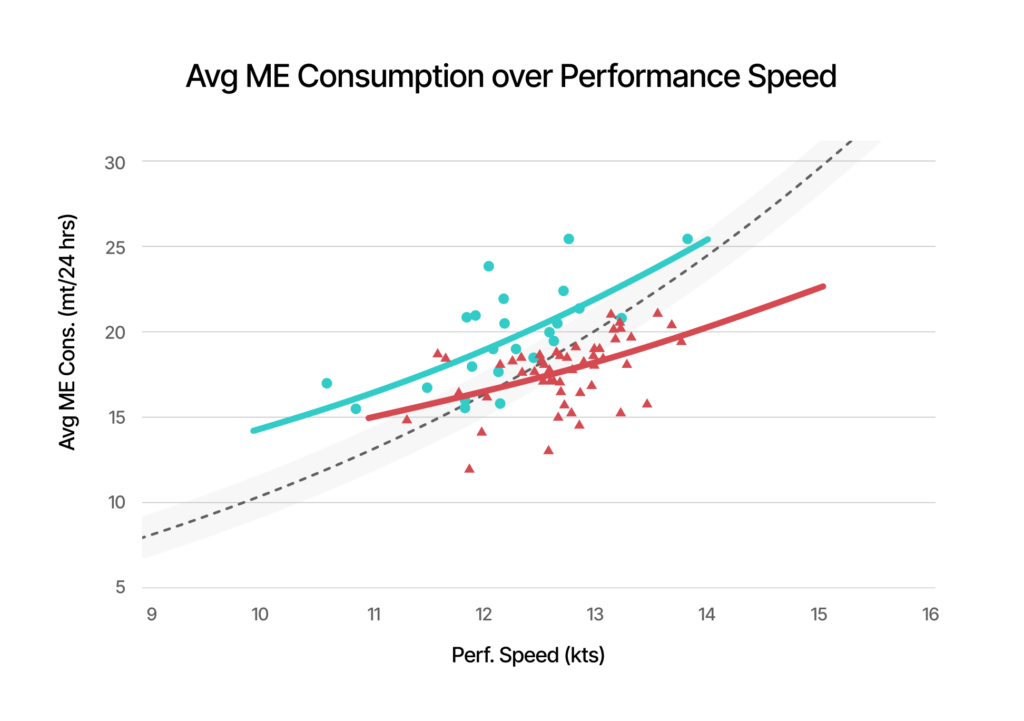

A performance analysis conducted by Stolt Tankers proved XGIT-PROP provided 3-4% fuel savings over a period of six months without decrease in efficiency and damage to the coating.

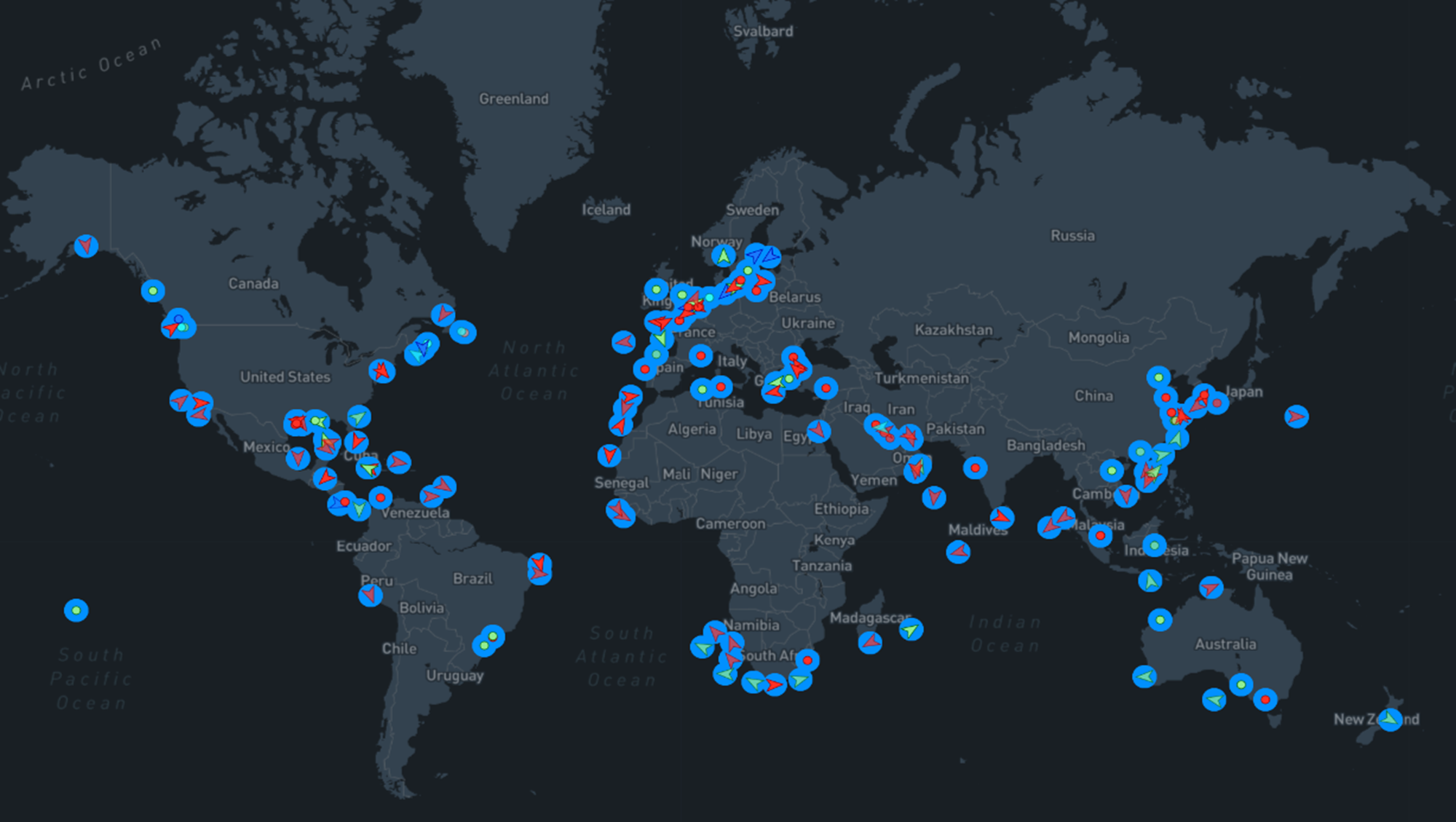

We are committed to leading the shipping industry towards a more environmentally friendly future by providing the world’s most sustainable and effective coatings biofouling management solutions.